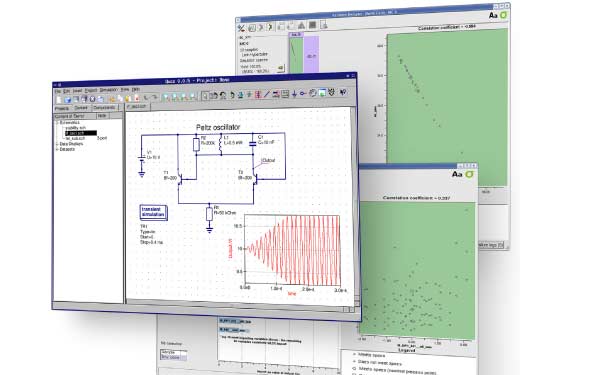

CIREX's knowledge in the area of casting simulations guarantees a stable process. Determining the proper casting configuration during production is a relatively complex process and the results are not always known beforehand. The casting process therefore needs to be simulated with a computer program. A casting simulation is a 3D model, which simulates the entire casting process. CIREX has used the same simulation software for many years and has built up considerable practical experience and knowledge. Casting simulations provide a high degree of process certainty, prevent technical problems and ensure that a project does not encounter delays.

How to use damon ps2 bios. SUTCAST casting simulation will optimize your casting parts resulting in lower cost and higher productivity. Grand theft auto episodes from liberty city cheats ps3 jetpack. To find out how you can get 88 days free trial to see how SUTCAST works for you please go to the contact us page and fill up the request form. SOLIDCast - Casting Simulation Software. SOLIDCast Casting Simulation software is the world's most popular pc-based solidification modeling system and cast design software used in the casting industry.SOLIDCast is developed after analyzing and focusing on the real time issues & problems when designing and making solid casts. Practical die casting geometries are quite complex. Cartesian grids introduce high stair-casing errors near the boundaries. Thus, OpenCast uses unstructured grids with tetrahedral and hexahedral finite volumes. First, a tetrahedral mesh is generated using the open source software GMSH. Tetrahedral elements have higher cross diffusion terms due.

Important parameters during casting simulations include:

- design of the gating system

- the choice of steel alloy

- air permeability in the ceramic mould

- temperature during casting

- the product's coagulation behaviour

Casting Simulation Open Source Word Processor

3D CASTING SIMULATION PREVENTS EXPENSIVE PROTOTYPING

Win 7 ultimate 32 bit iso activated. As CIREX has the software for performing casting simulations, we can make a significant contribution to the ultimate design and, with this, to the quality of the cast piece. We estimate that more than 90% of the errors in casting usually occur due to design errors and that only 10% are actually attributable to production problems. Many design errors can be observed on time using simulation software. After this, the design or the process parameters can be adapted. This ensures that no problems arise during the production of the casting.

The high cost of faulty casts is also prevented. Prototypes used to be made to detect errors; now this is done using 3D casting simulation. The so-called 'trial-and-error' procedure is now history. This saves you considerable time and money. The casting process and the cast piece can be optimised well using simulation software. It improves quality and reduces production costs considerably.

How to use damon ps2 bios. SUTCAST casting simulation will optimize your casting parts resulting in lower cost and higher productivity. Grand theft auto episodes from liberty city cheats ps3 jetpack. To find out how you can get 88 days free trial to see how SUTCAST works for you please go to the contact us page and fill up the request form. SOLIDCast - Casting Simulation Software. SOLIDCast Casting Simulation software is the world's most popular pc-based solidification modeling system and cast design software used in the casting industry.SOLIDCast is developed after analyzing and focusing on the real time issues & problems when designing and making solid casts. Practical die casting geometries are quite complex. Cartesian grids introduce high stair-casing errors near the boundaries. Thus, OpenCast uses unstructured grids with tetrahedral and hexahedral finite volumes. First, a tetrahedral mesh is generated using the open source software GMSH. Tetrahedral elements have higher cross diffusion terms due.

Important parameters during casting simulations include:

- design of the gating system

- the choice of steel alloy

- air permeability in the ceramic mould

- temperature during casting

- the product's coagulation behaviour

Casting Simulation Open Source Word Processor

3D CASTING SIMULATION PREVENTS EXPENSIVE PROTOTYPING

Win 7 ultimate 32 bit iso activated. As CIREX has the software for performing casting simulations, we can make a significant contribution to the ultimate design and, with this, to the quality of the cast piece. We estimate that more than 90% of the errors in casting usually occur due to design errors and that only 10% are actually attributable to production problems. Many design errors can be observed on time using simulation software. After this, the design or the process parameters can be adapted. This ensures that no problems arise during the production of the casting.

The high cost of faulty casts is also prevented. Prototypes used to be made to detect errors; now this is done using 3D casting simulation. The so-called 'trial-and-error' procedure is now history. This saves you considerable time and money. The casting process and the cast piece can be optimised well using simulation software. It improves quality and reduces production costs considerably.

INVOLVE CIREX EARLY IN THE DESIGN PROCESS

If our engineers can be involved in the design process early, our specific knowledge of casting and coagulation simulations can provide you with huge benefits. Thanks to ESI (‘Early Supplier Involvement'), a significant degree of design optimisation is made possible.

So when tendering a cast piece, do not choose simply the lowest price, but evaluate the quality that can be offered as well. The possibility of combining simulation software ('theory') with our technicians' years of experience ('practice') provides many advantages and reduces your costs.

* ESI (‘Early Supplier Involvement')

The supplier is involved early in the design process to contribute supplier knowledge in a timely manner: the potential results include significant cost reductions and simplification of the design and/or product improvement.

Die Casting Simulation Software

Benefits of casting simulations

Casting Simulation Open Source Software

- predicting turbulence or laminar flow of the liquid steel during casting

- detecting possible inclusions

- predicting solidification (behaviour & time)

- predicting tensile forces and deformations during the cooling of the cast piece

- improved product quality

- robust casting process

- less re-smelting, reduction of scrap

- shorter production times

- indicating areas in the cast piece that might have porosities and/or the formation of cracks